Category

- Cars for Sale

- Protomotive FAQ

- Services

- Accessories

- Engine Building Tools for Porsche

- DIY (Do it yourself)

- Protomotive Merchandise

- 911 Carrera / 930 Turbo (1978-1989)

- 964 Carrera / Carrera 4 (1989-1994)

- 993 Turbo 993 Carrera (1994-1998)

- 996 Turbo / GT2 / GT3-1 / 996 Carrera / 986 Boxster

- 997 Turbo / GT2 / GT2RS / GT3-2 / 997 Carrera / 987 Boxster

- 991 Turbo / GT2RS / GT3-3 / Carrera / Cayman / GT4 / 718 / 981 Boxster

- 992 Turbo Carrera GT3 GT4

- Panamera (970/971)

- Cayenne (955/957/958/9YA)

- Macan (95B/95B-2)

This is from our Youtube video: how do dual disc clutches work. The link is at the bottom of this page if you’d prefer to watch vs. read 🙂 But we figured you may want to study up and read along at your own pace, so enjoy!

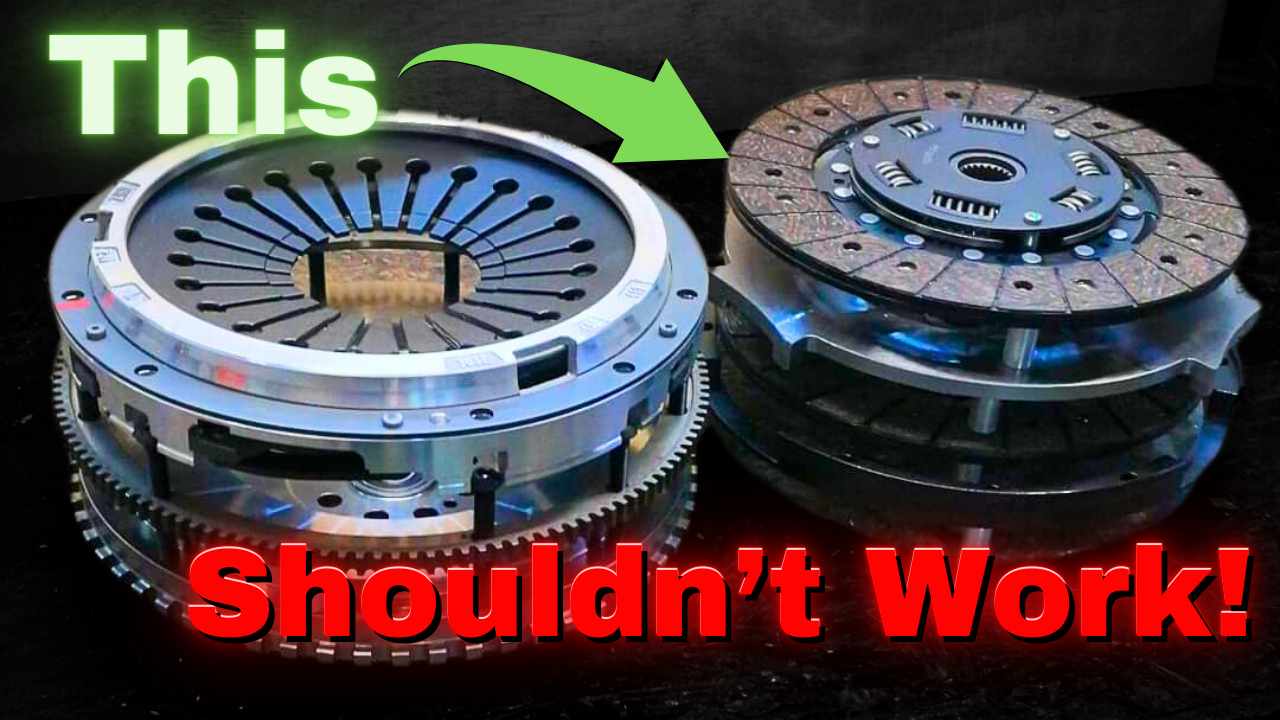

Dual Disc Clutches can be a bit of a conundrum. How do they even work? In this video, we’ll explain what they are, how they’re designed, what advantages they have, and nail this question down!

Remember back in high school physics class when you learned F=un? Yes, you were probably daydreaming about that awesome super car you’d own some day…

Or getting in trouble throwing paper airplanes around

So maybe you just weren’t even paying attention; but, regardless, we’re going to take a look at why dual disc clutches seem to defy this basic physics principle.

You might be getting a drift of what I’m referring to here and what the problem is, but if you’re not yet, we’re going to dive deeper into this.

What is a dual disc clutch?

Dual disc clutches are a high-performance clutch system for manual transmissions that can literally double the torque capacity of your vehicle compared to a single disc system. They work by using two friction discs instead of one, which allows them to handle more torque, more heat and last significantly longer.

How are Dual Disc Clutches designed?

As you can see, Dual disc clutches are similar in design to single disc clutches since they both use flywheels, pressure plates, clutch discs and so on. But the major difference is they use two friction discs instead of one. Which is a hint to the answer we’re after here… So, remember that. The two discs are mounted back-to-back with a floater plate sandwiched in between.

When the clutch is engaged, the pressure plate forces the two discs together, which transmits power from the engine to the transmission.

Alright, well that gives us a little more information. Here we have two discs. So we have doubled the surface area which should double the torque, right? Well, from above we had F=un. Where F=The sliding force provided by the u part which is the coefficient of friction and n being the force pushing them together, also known as the (N)ormal force… hmmm. There’s no surface area even in that equation… What gives? So doubling the surface area isn’t what’s giving us the increase in torque holding capacity.. Or is it?

What are the Advantages of Dual Disc Clutches?

The main advantage of a dual disc clutch is that it can handle more torque than a single disc clutch. Because the two discs provide twice the surface area for friction, which allows them to dissipate heat more effectively. Hmm, well kind of. Doubling the surface area does allow twice the surface to reject the heat and It provides twice the surface area for wear, so you’ll get longer life out of them vs. an equivalent single disc clutch. Dual disc clutches are also less likely to slip than single disc clutches, which makes them ideal for high-performance applications. Yes, that’s true as well, and actually the whole point of going to a dual disc clutch vs. a single, but still not answering why they hold more torque when the basic physics equation isn’t making sense. Yet.

Why dual disc clutches hold more torque.

So the reason the F=un doesn’t seem to work is we’re doubling the surface area which typically reduces the pressure on any given square inch of the friction surface. Let’s say you put 1000 lbs. of force on 10 square inches of disc. Each square inch would now have 1000 lbs/10 in^2 or 100 lbs / in^2 of pressure acting on it. Now let’s double the surface area and try this again. We have 1000 lbs. of force again, but this time 20 square inches of disc. So now we have 1000 lbs / 20 in^2 or 50 lbs / in^2 of pressure… Huh? That just went the wrong way? Well doubling the surface area with half the pressure on each given area ends up canceling each other out and we end up with the same holding capacity… But that would only be if we were doubling the surface area of a single disc or a block sliding across the floor like we did back in physics class…

Here is the trick…

Since the discs are stacked vs. a single surface, each disc gets the FULL 1000 lbs. across its 10 in^2 of surface or now the equivalent of 2000 lbs. of force acting on 20 in^2 which gives us the same exact pressure or 100 lbs / in^2 on each friction surface. Still sounds funny, right? Doubling the pressure and the surface area still gives us the same pressure…

Let’s go back to the sliding block example. Since the discs are stacked and each one has the full 1000lbs acting on it, it’s like having two blocks now equalling twice the weight, or n in the equation with the same friction coefficient, u, which finally doubles the F or Force in the equation…

So, by stacking the discs, allowing the full pressure of the pressure plate to act on each disc and not be divided by them, we’re finally able to double the torque capacity of the system by adding more discs!!!

How about more discs?

Yes, we could do more discs. Like the infamous Ducati dry plate clutch that runs a multi plate clutch. (b-roll to a ducati idling with the clutch rattle sound) Or the Carrera GT that also has a multi-plate clutch disc. (b-roll Carrera GT ripping by) Formula one cars and Top Fuel dragsters have been using this technology for years as well! Formula one uses multi-plate clutches to be able to reduce the overall diameter thus the rotational inertia of the system while Top fuel needs to be able to handle tons of torque and heat during the launch. Even automatic transmissions like in the 996 and 997.1 turbo use multi-plate clutches in the gear stacks. Little tiny ones, but with anywhere from 4 to 10 plates stacked with friction surfaces between each plate.

Won’t the clutch be too stiff with all that pressure?

Well, no… We’ve not increased the pressure plate or the 1000 lbs in these examples at all to increase the torque capacity. In theory, we could use a dual disc with only a 500 lb pressure plate and have a super light clutch pedal but hold the same capacity as a single. But why would we do that? We’re here because our single disc clutch is either slipping under power, our single disc clutch is undrivable due to a heavy pressure plate, or it’s chattery due to a metallic clutch disc being used. So, if we keep the same pressure plate or increase it over the stock pressure plate with the Sachs 764 or 487 to gain not only double, but another 15 to 30% on top of that for a whopping 230 to 260% torque increase between them. All while driving and feeling like a stock clutch!

Conclusion

You may or may not have questioned why dual disc clutches work. But I thought it was fun enough (lol, no pun intended) to bring up since the basic formula at first glance just doesn’t seem to work out. We know they work. We’ve used them in many applications throughout history, but unless you think about it right, it just doesn’t line up. Kind of like a similar argument about wider tires shouldn’t grip any better according to the same formula… But we’ll have to save that for another time.

Link to Protomotive Dual Clutch kit:

Written by Protomotive

Trevor Morris2024-04-22Todd is the ultimate godfather of Porcshe! His knowledge and informative videos have been invaluable to me as a Porsche enthusiast. I'm incredibly grateful for his expertise and guidance. I had an intermittent problem with my 996tt that has plagued the car for 6 years, no shops were able to figure out the problem. I emailed Todd and he narrowed it down within a couple emails, and sure enough he guided me to the problem and it was a simple fix in the end. Not to mention Todd's tuning skills are off the charts, as the car also traps 144mph in the 1/4 mile. Keep up the fantastic work, Todd!

Trevor Morris2024-04-22Todd is the ultimate godfather of Porcshe! His knowledge and informative videos have been invaluable to me as a Porsche enthusiast. I'm incredibly grateful for his expertise and guidance. I had an intermittent problem with my 996tt that has plagued the car for 6 years, no shops were able to figure out the problem. I emailed Todd and he narrowed it down within a couple emails, and sure enough he guided me to the problem and it was a simple fix in the end. Not to mention Todd's tuning skills are off the charts, as the car also traps 144mph in the 1/4 mile. Keep up the fantastic work, Todd! Chris Roundtree2024-02-19I wanted to thank Todd at Protomotive Motorsports for going above and beyond when he helped me sort out a problem with a product that I had purchased from another vendor. Todd seems to always have the knowledge to put together the best combination of parts to make any model Porsche not only go fast or handle better, but do it reliably. He always answers the phone. In the rare event he doesn’t pick up he gets back to you within twenty four hours. Emails get responded to just as quick. I really appreciate having some like Todd available when working on any Porsche as you know he has a proven setup to satisfy any goal. Thx Chris

Chris Roundtree2024-02-19I wanted to thank Todd at Protomotive Motorsports for going above and beyond when he helped me sort out a problem with a product that I had purchased from another vendor. Todd seems to always have the knowledge to put together the best combination of parts to make any model Porsche not only go fast or handle better, but do it reliably. He always answers the phone. In the rare event he doesn’t pick up he gets back to you within twenty four hours. Emails get responded to just as quick. I really appreciate having some like Todd available when working on any Porsche as you know he has a proven setup to satisfy any goal. Thx Chris Antreas Smilas2024-01-22Super in every way..2 years now in ecu and tcu perfect power delivery ,reliable,and fast as mr Todd promise in number...i can say even i draggy was the same numbers as promise to achieve with this set up.

Antreas Smilas2024-01-22Super in every way..2 years now in ecu and tcu perfect power delivery ,reliable,and fast as mr Todd promise in number...i can say even i draggy was the same numbers as promise to achieve with this set up. Taylor Berg-Kirkpatrick2024-01-04Todd has got to be the world's expert in forced induction Mezger Porsche engines. I've worked with a bunch of mechanics, tuners, engine builders across multiple Porsches over multiple decades... and Todd has been the most helpful and knowledgeable of the bunch. And this has even been true while working with him remotely! (I'm in CA and he's in AR.) Just by looking at my logs and hearing about my engine rebuild, he's been able to diagnose stuff that in-person mechanics have not been able to. For example, Todd was the only person looking at my car to suggest a problem with a BRV could explain some of the weird behavior... following his advice, I dug in myself... lo and behold, torn BRV diaphragm on bank 1! Wow! Further, Todd has the most experience tuning these cars of any tuner I've worked with. Tune is absolutely solid and safe. Very very confident in his work!!! Absolute strongest possible recommendation!!

Taylor Berg-Kirkpatrick2024-01-04Todd has got to be the world's expert in forced induction Mezger Porsche engines. I've worked with a bunch of mechanics, tuners, engine builders across multiple Porsches over multiple decades... and Todd has been the most helpful and knowledgeable of the bunch. And this has even been true while working with him remotely! (I'm in CA and he's in AR.) Just by looking at my logs and hearing about my engine rebuild, he's been able to diagnose stuff that in-person mechanics have not been able to. For example, Todd was the only person looking at my car to suggest a problem with a BRV could explain some of the weird behavior... following his advice, I dug in myself... lo and behold, torn BRV diaphragm on bank 1! Wow! Further, Todd has the most experience tuning these cars of any tuner I've worked with. Tune is absolutely solid and safe. Very very confident in his work!!! Absolute strongest possible recommendation!! N K2024-01-04Todd and his team are true professionals and they always provide excellent customer service, quality parts they sell and very reliable engine builds. This is very rare in our industry today. Great job Protomotive!

N K2024-01-04Todd and his team are true professionals and they always provide excellent customer service, quality parts they sell and very reliable engine builds. This is very rare in our industry today. Great job Protomotive! raphael wirth2023-05-29Todd est l homme de la situation…. Des difficultés ou des problèmes pour régler le problème? Todd trouve la solution malgré la distance ( je suis français) Merci à lui et son équipe pour leurs conseils … Maintenant mon 997 turbo fonctionne à merveille et est un véritable avion de chasse! Je recommande a 1000% !!! À bientôt pour d autres évolutions !!!

raphael wirth2023-05-29Todd est l homme de la situation…. Des difficultés ou des problèmes pour régler le problème? Todd trouve la solution malgré la distance ( je suis français) Merci à lui et son équipe pour leurs conseils … Maintenant mon 997 turbo fonctionne à merveille et est un véritable avion de chasse! Je recommande a 1000% !!! À bientôt pour d autres évolutions !!! Adam McGregor2023-04-05I don’t think there is a better shop to shop entrust your Porsche to then Protomotive and the Knighton’s. Just search there name with 993 and you can start to get an idea of their storied history of building monster but reliable 911 Turbos! I have over 12 years and 30k miles (street, autox & track) on the Protomotive set up on my 997tt and it has never skipped a beat!

Adam McGregor2023-04-05I don’t think there is a better shop to shop entrust your Porsche to then Protomotive and the Knighton’s. Just search there name with 993 and you can start to get an idea of their storied history of building monster but reliable 911 Turbos! I have over 12 years and 30k miles (street, autox & track) on the Protomotive set up on my 997tt and it has never skipped a beat! Piotr L. Pawlak2023-04-05Unfortunately they could not resolve my issue, but Todd tried very hard to find some other resolutions. He was very helpful and responsive.

Piotr L. Pawlak2023-04-05Unfortunately they could not resolve my issue, but Todd tried very hard to find some other resolutions. He was very helpful and responsive. B W2023-03-23Todd is by far the most professional and knowledgeable Porsche person I have ever worked with in my life and I have had many cars and have been doing this for over 20 years. He not only knows how to overcome every single problem, but also knows how to explain exactly what he is doing and brings the car to a point where it feels like stock even though it has double or triple the power. If you go anywhere else you would be making a mistake

B W2023-03-23Todd is by far the most professional and knowledgeable Porsche person I have ever worked with in my life and I have had many cars and have been doing this for over 20 years. He not only knows how to overcome every single problem, but also knows how to explain exactly what he is doing and brings the car to a point where it feels like stock even though it has double or triple the power. If you go anywhere else you would be making a mistake Alex May2023-02-20The engineers at Protomotive are absolutely the best. They performed extensive work on my Porsche GT2 and I literally could not be happier. Their work, attention to detail, problem solving and communication with me were all next level. Customer service is remarkable. I had a question while at the track, on a Saturday, and Todd immediately responded to my questions. Class act.Load more

Alex May2023-02-20The engineers at Protomotive are absolutely the best. They performed extensive work on my Porsche GT2 and I literally could not be happier. Their work, attention to detail, problem solving and communication with me were all next level. Customer service is remarkable. I had a question while at the track, on a Saturday, and Todd immediately responded to my questions. Class act.Load more

Leave a Reply

You must be logged in to post a comment.